As a leader in global flight case hardware, we’re always working hard to improve the quality of our components and deliver the best in the industry for our customers to rely on.

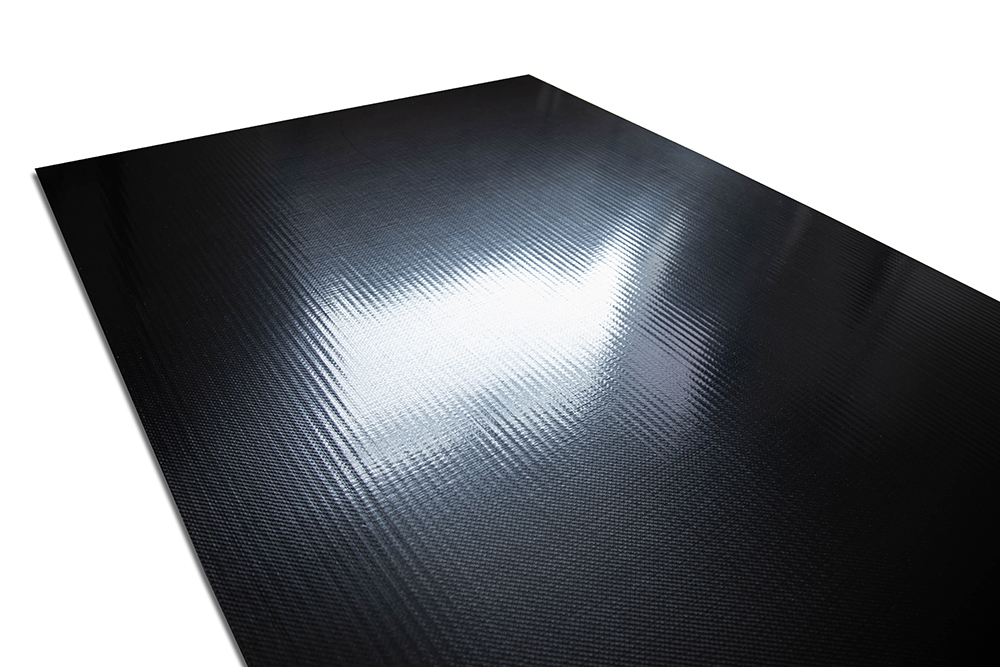

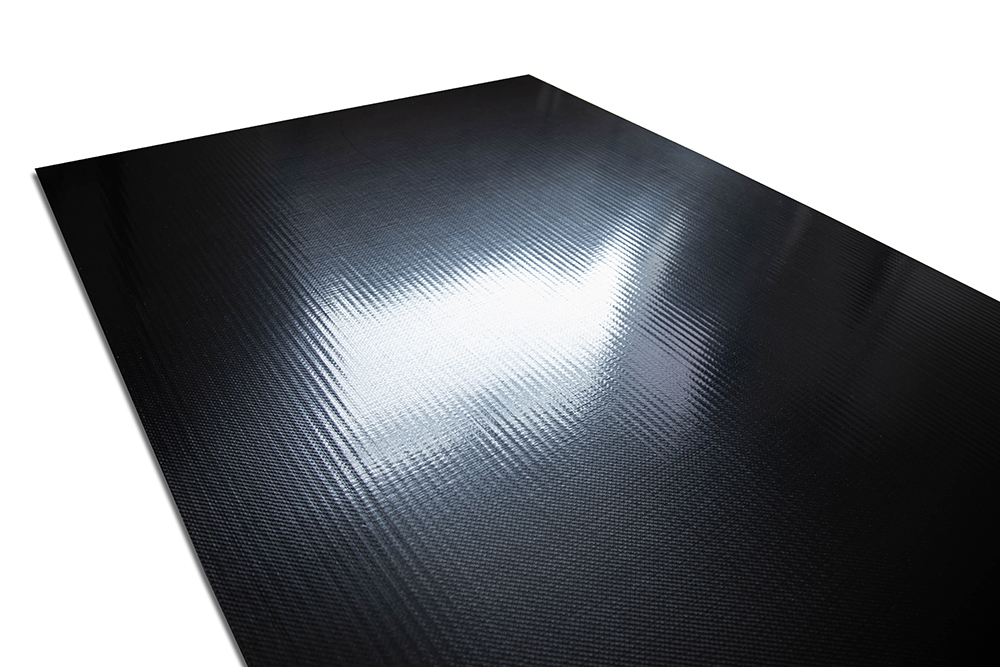

Now, we’re very proud to release our latest innovation: the UltraFlite case panel. This technologically advanced panel was created to improve on plywood in every way and comes with an impressive list of features that will upgrade any case while being better for the environment, too.

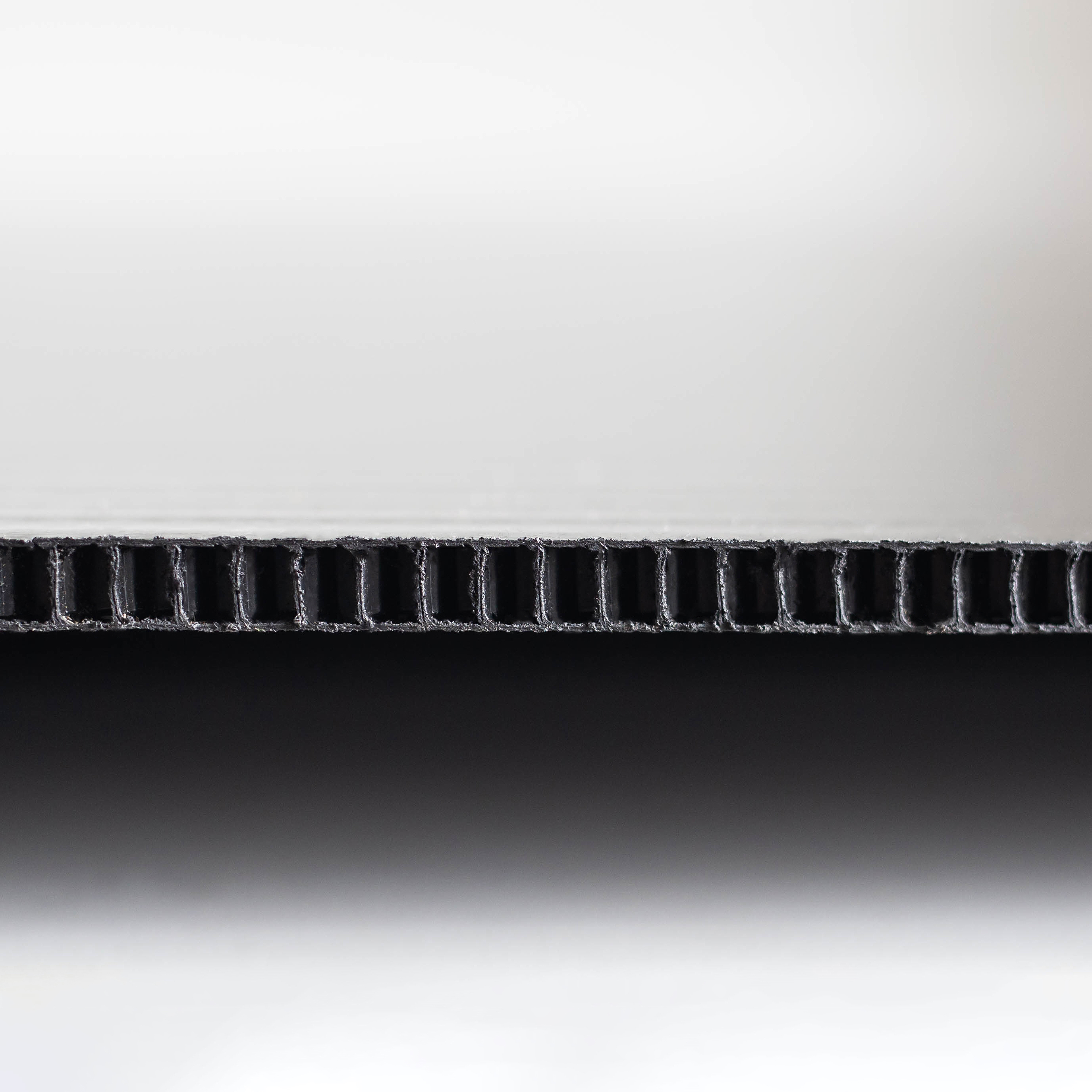

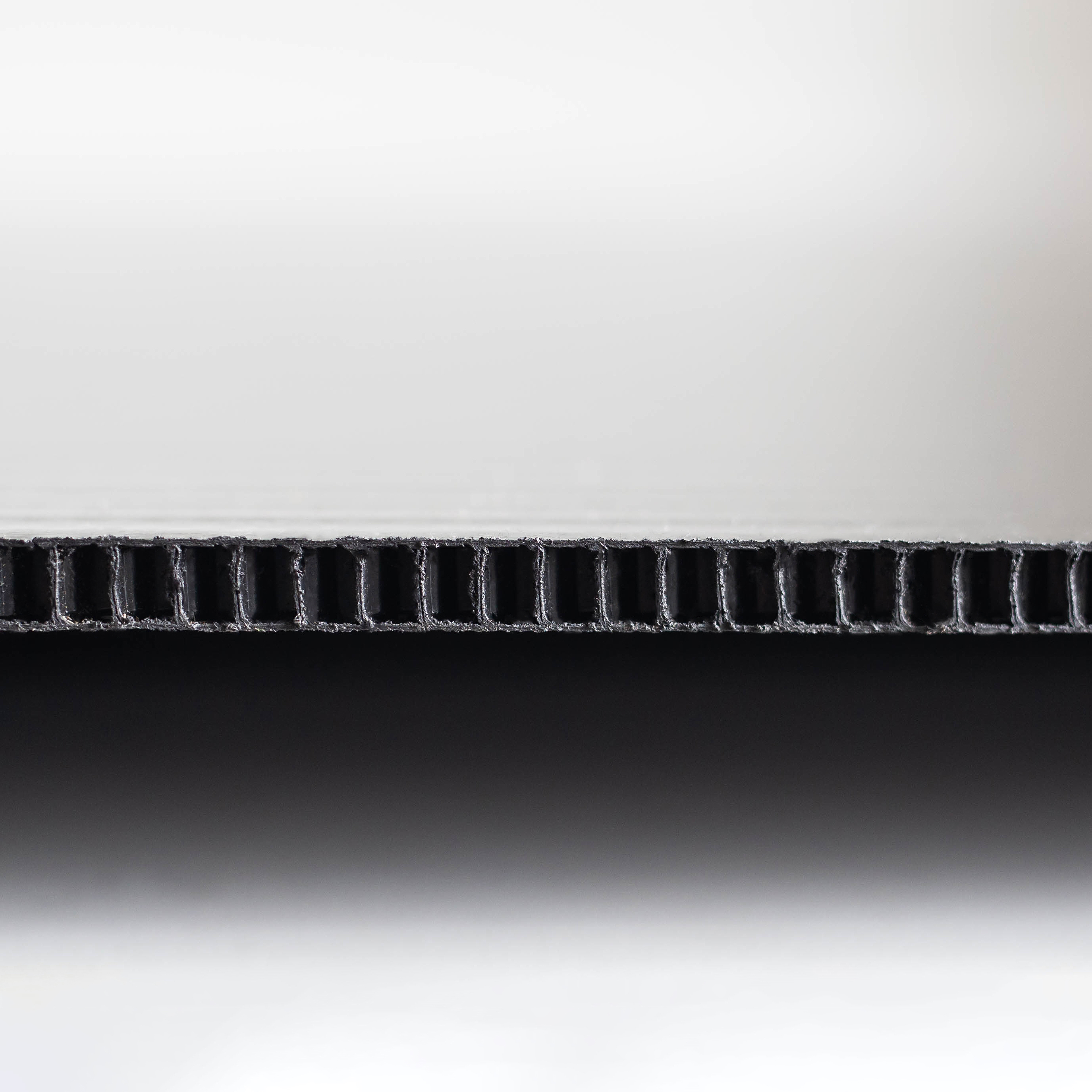

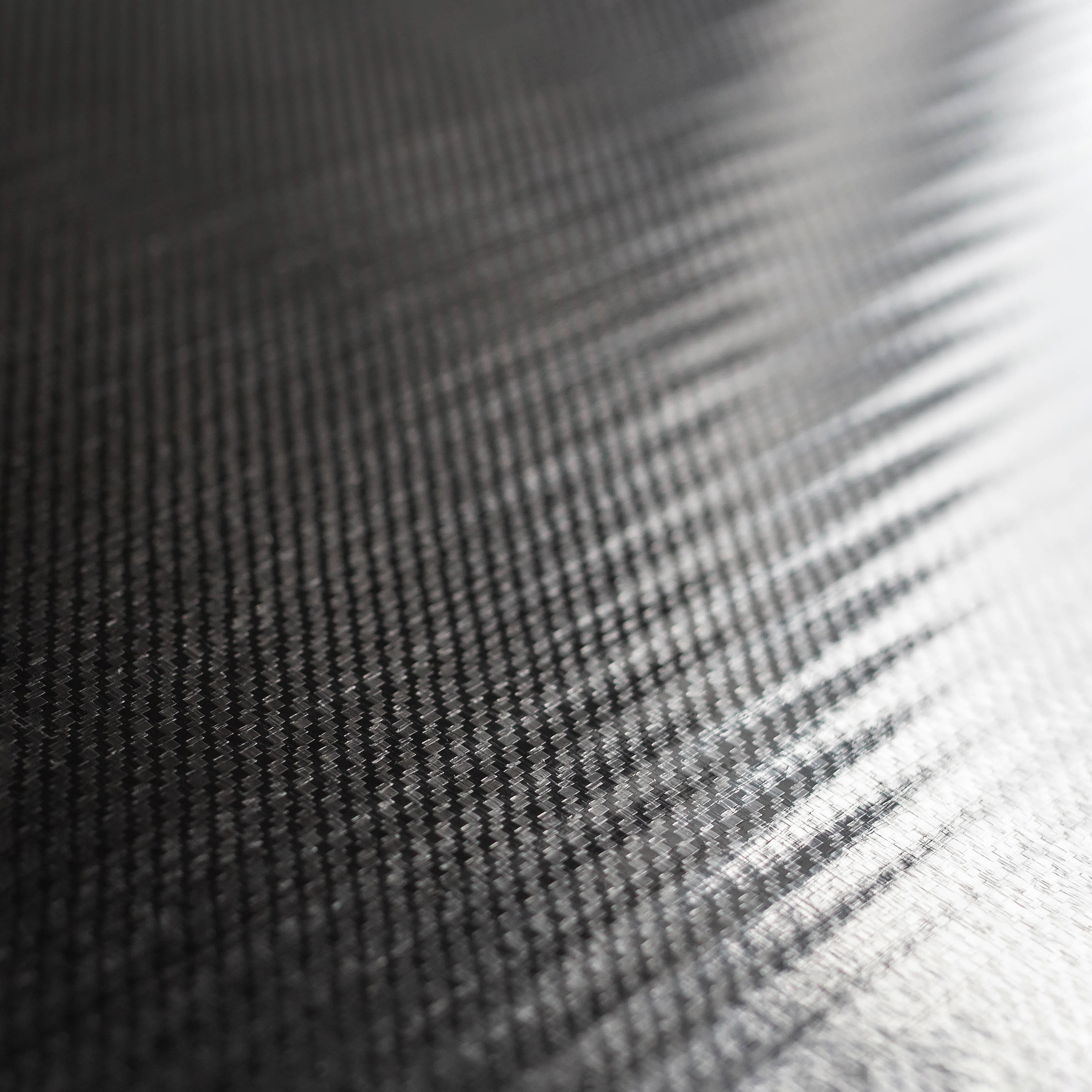

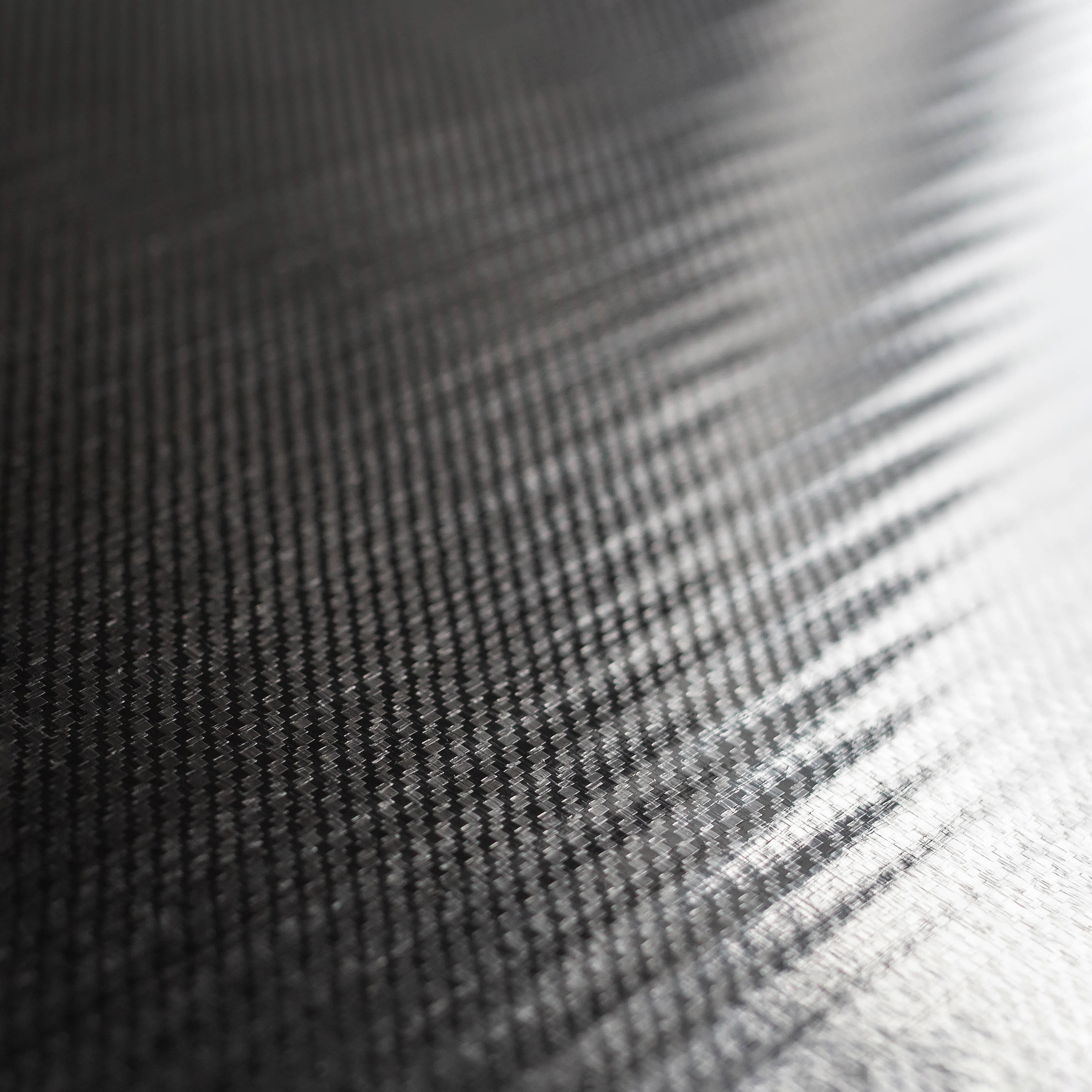

Created to be much lighter than plywood but remain both durable and weather resistant, it’s made using a hollow honeycomb core sandwiched by two highly stretched polypropylene fibre skins. This advanced construction method gives each sheet the durability to handle tough use, resistance against weather and chemicals and the lightness that makes it so desirable. Swapping plywood for UltraFlite will reduce case weight on average by 30% - 40% so they’re more cost-effective when transporting as well as easier to lift and carry.

As a responsible manufacturer, we design our products with their impact on the environment in mind. We want to create products that are ecologically sound so we’ve ensured that UltraFlite is 100% recyclable. Not only that, but compared to plywood panels it takes fewer resources to manufacture and lasts longer so has a smaller production footprint.

We think UltraFlite panels not only improve upon what they do but are a sound investment for the future and the ideal choice for case builders.