If you are looking to build a flight case, you have probably googled flight case hardware and found thousands of results which can be very overwhelming. Choosing the right hardware for your flight case is essential to ensure that your case performs properly.

There are a few factors to consider when deciding what flight case hardware you should use...

What is your case being used for?

Depending on what you are using your flight case for will change the requirements of the hardware:

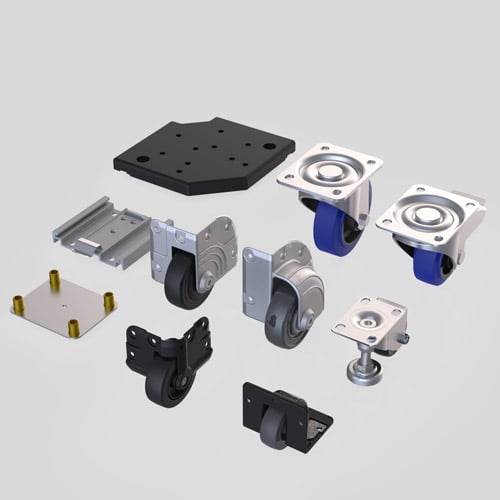

- Will you need castors to make transporting your case easier?

- Do you require case foam or carpet for additional protection?

- Do you need to easily access cables or equipment?

- Will your case be housing an rack and needs the highest levels of impact protection and shock absorption?

- Do you need to manage the temperature inside the case?

- Do you need to have multiple compartments?

- Do you require any storage areas?

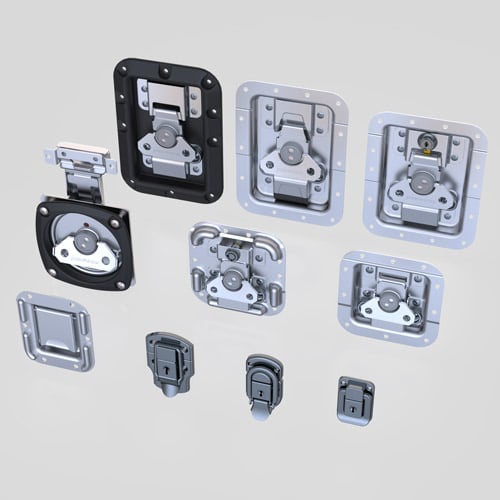

- Does your case need to be locked?

How often will your flight case be in use?

If your flight case is going to be frequently used and in transit, choosing stronger hardware made from steel may be a better option than using plastic alternatives.

Where will your case be used?

For many industries, a flight case needs to be robust enough to handle frequent use, various environmental factors and weather conditions. For example, if you know that your flight case will be used outdoors at festivals, events and gigs, you need to choose hardware that is weather-resistant in order to keep your case contents secure and protected. You may also want to consider using a hardwearing polypropylene panels to construct your case from instead of plywood as a lightweight alternative.

Who will be using and manoeuvring your flight case?

A large flight case or trunk style case will likely need more than one person to transport it, so thinking about how many handles and where they are placed is important. Castors allow you to push and pull the case with ease, even when loaded with heavy items, and automatic aligning swivel castors makes lifting and stacking cases fast and safe, reducing the need to manually set the castors into position. You may also want to consider flight case latches that are easy to operate, like the popular MOL range which features Penn Elcom’s innovative automatic open/close system and patented MOL automatic positioning latch system which allows the user to open and close with one hand, even in dark environments.

Are there any aesthetic considerations?

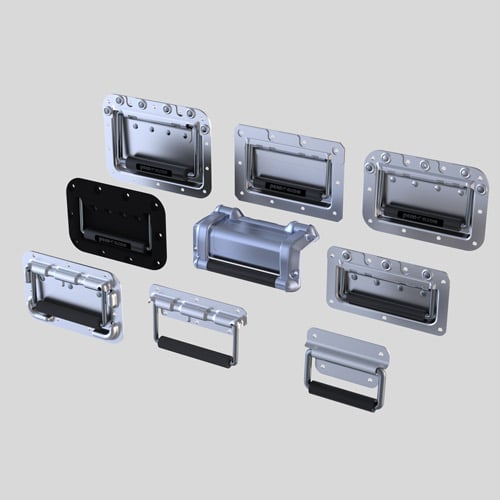

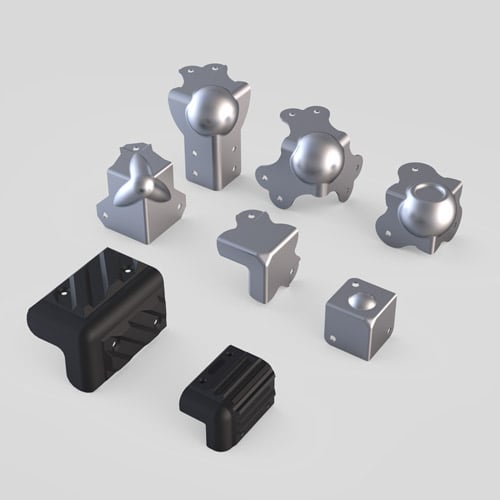

Flight cases can be built in any configuration, size and shape, but they can also be made in a large variety of colour combinations to meet requirements and reinforce customer branding. Flight case panels and laminates are a great way to add brand colours to a case, but you could also consider your flight case hardware – the industry standard is to use zinc plated or steel hardware which as a silver finish, but black hardware is also a popular choice to change the entire look of a case.

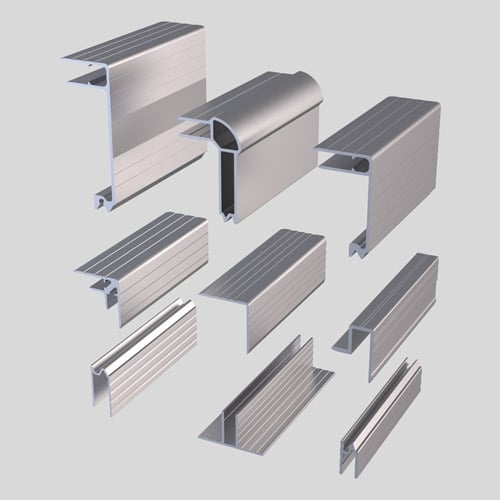

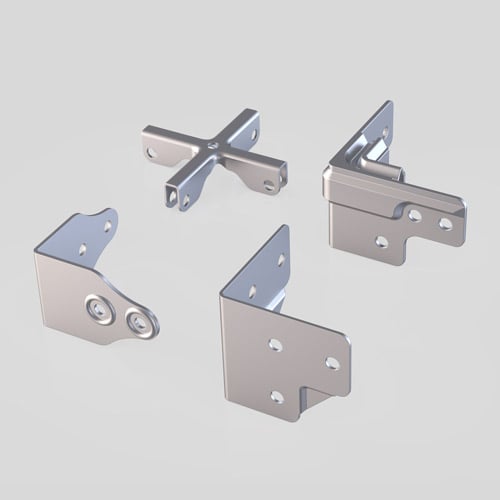

To ensure your case is long-lasting, durable and reliable, you need to invest in high quality hardware. Investing in the right hardware will result in improved and prolonged performance, reducing the number of repairs and increasing your reputation as a superior case builder. Penn Elcom’s range of flight case hardware has been expertly designed and manufactured to withstand the rigours and demands of being on the road. Our case hardware is globally renowned by flight case builders and pro audio and AV professionals to protect their valuable equipment wherever they are.