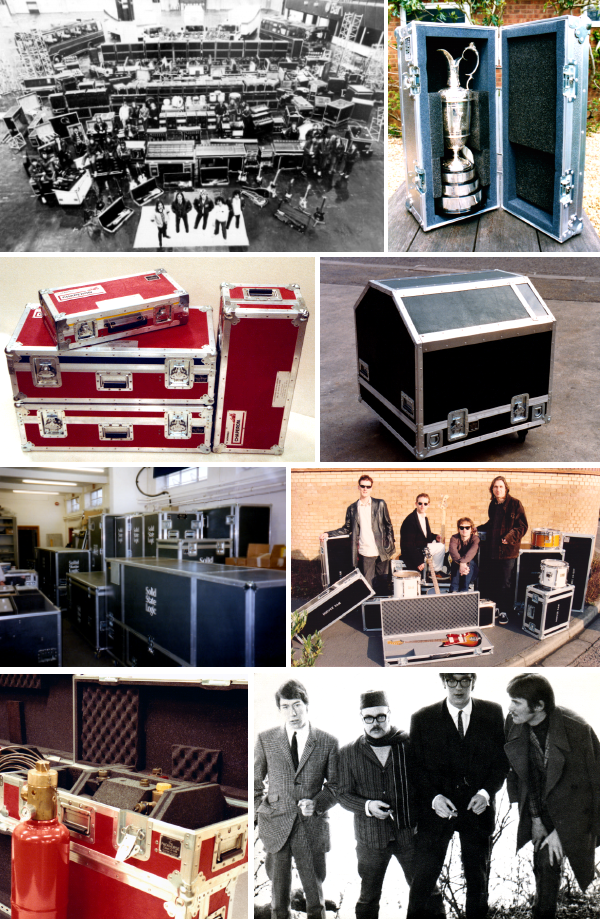

Rock n Roll aficionados among our readership might be aware that David Gilmour, member of the legendary band Pink Floyd, recently auctioned a huge collection of his personal guitars to raise money for climate charity. History was made at renowned auction house Christies as the final showpiece item - his iconic black Fender Stratocaster - achieved the highest ever bid on a guitar with the gavel finally coming down to $3,975,000.

Our own chapter of this amazing story had already begun, however, with the penultimate item of the day: Lot 126. It was the flight case that had dutifully housed and transported the precious ‘Black Strat’ safely to show after show of The Wall Tour and beyond.

Commissioned for David in 1979, the case was custom-built by Packhorse Case Company and assembled with Penn Fabrications hardware (in the days before Penn merged with Elcom! -ed.). Thanks to our own flight case maestro Sam Robinson, we were fortunate to get a chance to interview then-owner Peter Robinson for a truly unique insight into the world of rock n roll flight cases:

Hi Peter, thanks very much for your time! Let’s start at the beginning - can you recall the request to build the case?

Pink Floyd had a company called Britannia Row that looked after all their equipment who would have placed the order. Dave Gilmour’s guitar tech would have contacted us to discuss the details of the case and any specific requirements that deviated from the norm, (extra pockets, deeper cutouts, colour) etc.

And what about the case itself? What made it unique?

It’s difficult to be specific about the particular case because we made so many for all the players of the time, however, cases for touring bands followed a similar pattern. The case would be made to the highest spec like walls made from fibreglass laminated on marine plywood, double-sided aluminium angle and all Penn fittings. The inside would be fitted out with a polyurethane block cut to the shape of the guitar and if required, would also be lined with a deep pile fur fabric.

How did you first get into making flight cases?

I got into it by mistake really. My background was in the music/entertainment business but with a wife and three children to support, I was looking around for something that did not entail so much travelling and time away. I was talking about this with an old friend and business owner Rick Wakeman who was using a lot of delicate equipment so we started a case company to protect it all. After a few years, Rick was still very busy and touring all the time so I ended up with Packhorse, which had grown dramatically.

What do you think made your work so appealing to bands, especially?

We were successful probably because having been in that business, we knew the problems encountered by the crews. While travelling equipment around the world, gear had to work day after day with very little opportunity for repair or rebuild. Our designs made the cases easy to use while still protecting the equipment both cosmetically and physically.

What did you like about the Penn Elcom components that kept you choosing them?

When we first started manufacturing, all the hardware had to be imported from the US as there wasn’t any UK or European manufacture. This was very expensive with the freight cost and duty factor and we constantly had problems with delivery. We were based in High Wycombe and used a company called Penn Anodising, owned by Roger Willems who became a driving force behind the success of Penn Elcom. Roger talked to all the case manufacturers of the time, finding out what they wanted, and over the years supplied exactly what was needed.

Finally, could you perhaps share a memorable story our readers might enjoy?

Back in the late 70’s we were asked to construct a single case that could transport the new model Lotus F1 car in its entirety. It would be the biggest case we had ever made up to then. We built the case and delivered it to Norfolk Airport where it was loaded to transport the car to the States for testing. But when the Lotus crew arrived, they were told instead of the usual 747 they would be flying in a 707 - except now the case could not fit in the smaller hold. So they took the car back out, shipped it alone to the States and the empty case followed in the next available 747.

By the time the case arrived though, the car had been banned for technical infringements and was on its way back to England - so our case now went ahead to Brazil for the first race. The car eventually got to Brazil, was banned again, sent back to England and the case remained forever in Brazil.

Thank you very much for taking the time to share your experiences with us, Peter. We’re sure you’re proud to know that your case went for $175,000 - a little higher than its initial valuation of $2,000!

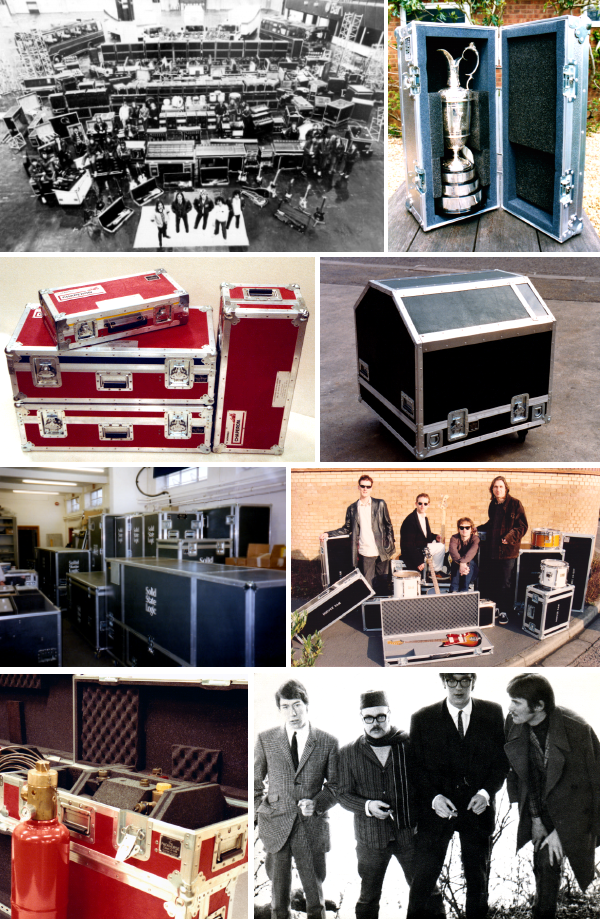

We're grateful to Sam and Peter for not only sharing the story, but also unearthing some amazing vintage photos of cases Packhorse built at that time. Bonus points if our readers can guess which handsome gentleman below is Peter himself!