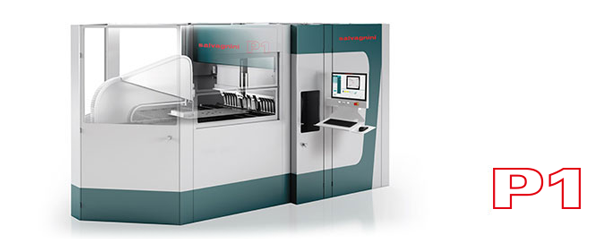

It’s been a busy month for the team at our Hastings, UK factory with all hands on deck preparing for the delivery and installation of a much-anticipated arrival: the new P1 electric panel folding machine.

Our powerful Salvagnini P4 has been the backbone of our sheet metal production team since 2017, taking us to new heights with its speed and ability. However, progress never sleeps at Penn and we’ve upgraded our production capabilities even further with the smaller yet uniquely powerful P1.

The high-tech model from Salvagnini is crafted with all the expertise and know-how we’ve come to expect from the leading manufacturer of electric panel benders. The P1 is designed to offer a smaller footprint which occupies less factory floor space. This enabled us to install it next to the P4 and operate them in tandem. Since it runs efficiently on low-watt electricity consumption, it fits well with our core ethos of reducing waste and reliance on resources.

With the new P1, our UK production team have been upgraded in many areas, not least in terms of quicker ‘load & fold’ times, especially for smaller items. Compared to older press-brake machines - several of which are in daily operation at our plant - the new electric models dramatically increase product output while maintaining our high-quality standards.

Job management has also been given a very welcome boost as well, with our trained production staff taking advantage of the new software capabilities the P1 offers. Now with dual operation, the P4 and P1 machines combine to fold multiple product types and sizes simultaneously. Before the P1’s arrival, operators clustered job types for effective time management but at the cost of extra scheduling work and less allowance for change.

It’s good news all around for Penn, not only for production but also for our colleagues as well. Now our expert operators have more opportunities to train junior staff, adding sought-after technical abilities to their skillset and helping to ensure a consistently advancing workforce for us.