Our extensive warehouse facilities have received much-anticipated updates this year in the way of Carousel and Shuttle storage systems.

Improving global organization, space utilization and efficiency, these smart dynamic storage systems are already having a positive impact on our productivity. In the UK, we have added these facilities to both our Washington and Hastings sites.

In Washington, they are populating their ten new storage shuttles and three carousels with our top-selling 500 items. Steven Langdon (UK Deputy Managing Director) said “On average, we pick over 3,000 times per month from our machines for all types of orders, 150 lines per day on average by one man. We can now pick a reasonable-sized hardware order in 2-5 minutes instead of 10-12 minutes. This improves the efficiency of the process and helps with safety in the department.” The shuttle machines move at 2m/s and can deliver a product within 45 seconds of selection! All machines are light guard protected for safety.

The shuttles in Washington are 10m in height and have a footprint of 9m2/ 968 sq ft. Each shuttle is made up of storage 62 storage trays with a capacity of 210kgs or 275kgs. The various sizes and weights of Penn Elcom’s product portfolio mean these shuttles are ideal to house a large variety of our parts; the maximum storage height of any item per tray is 700mm and each shuttle can hold up to 13000kgs of product when maximised or 90m3 of stock.

“The investment and installation of the machines allowed us to reduce our dispatch area working footprint by 43.8% (1400m2/2/15000 sq ft). Their installation also reduced the number of picking errors, the use of ladders; man riders and fork trucks in the area resulting in a safer working environment for our personnel and visitors” said Steven.

In Hastings, UK, we have added one carousel and five shuttles to increase efficiency and to maximize space on site – the Hastings facility is continually adding new machinery and innovative processes all of which require large areas for safe and streamlined performance.

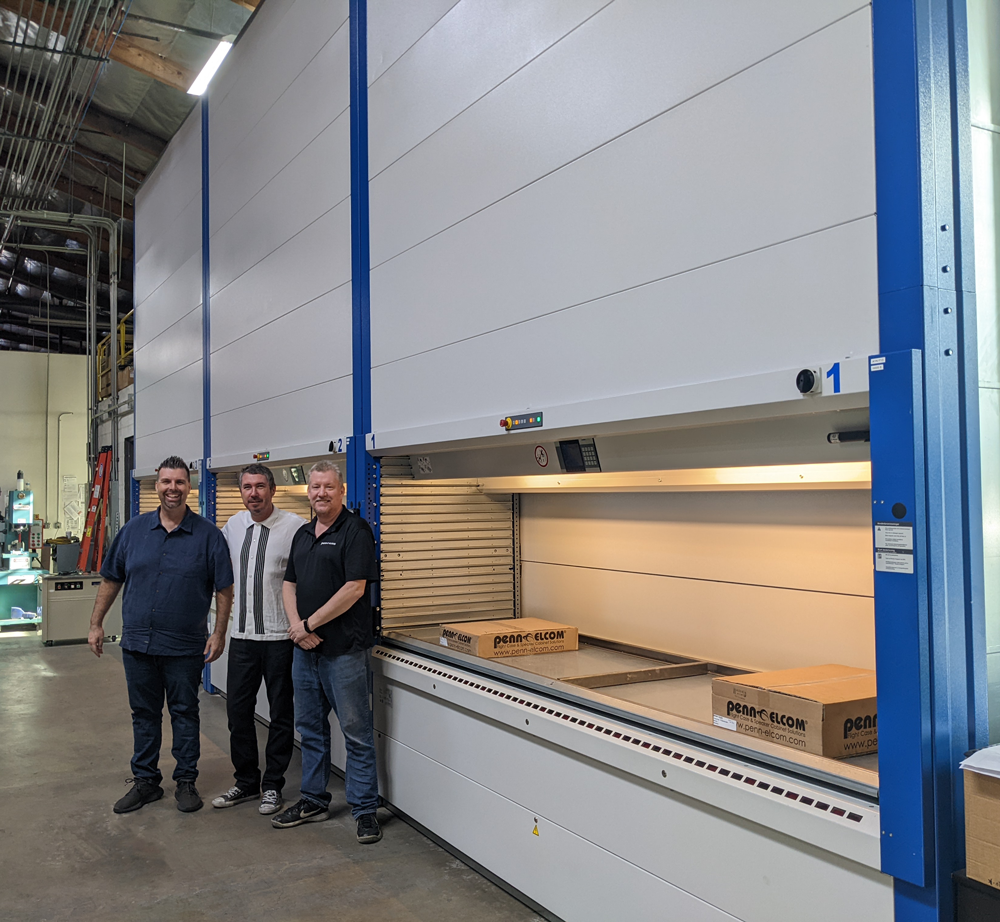

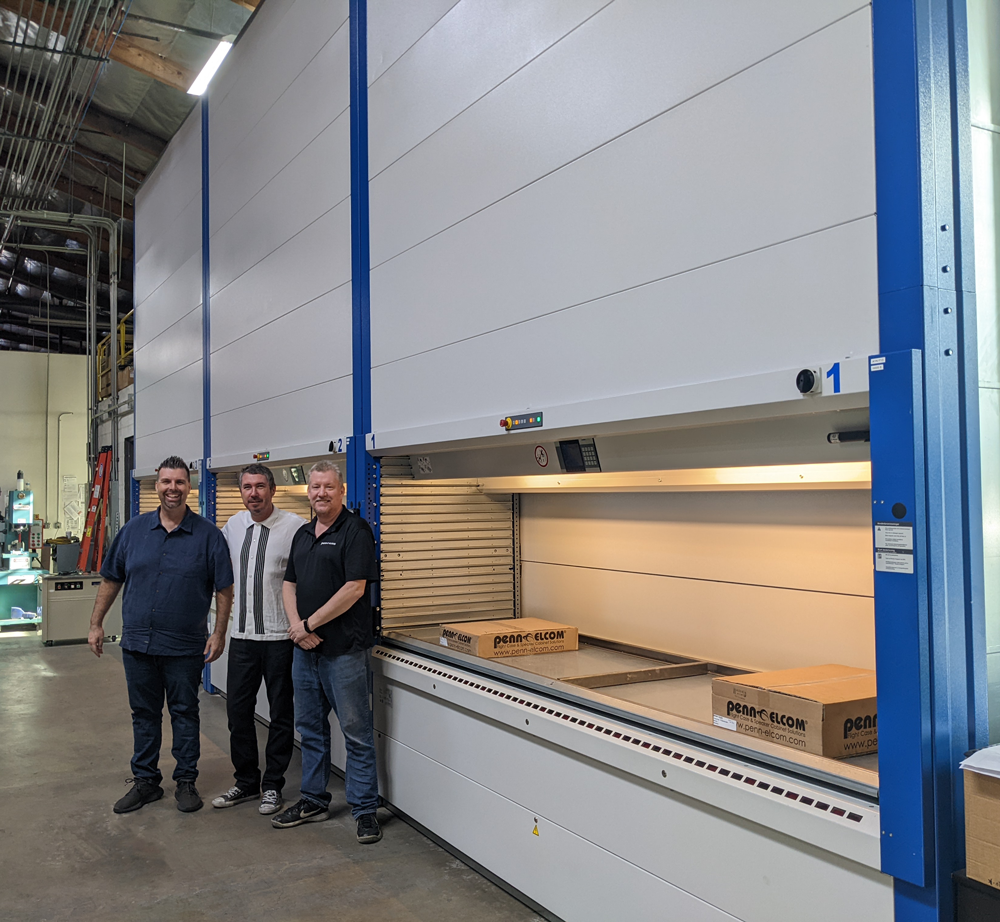

The California depot received three shuttles from Germany. Brent Wilcox, the Branch Manager of Penn Elcom California was very excited to receive them as he had already seen photos and videos of them working in the UK and was sure that they could make the California warehouse more state-of-the-art and more efficient, especially when it came to pulling customer orders.

The installation team came over and worked closely with Dave Smith, the California Depot’s resident electrician in order to get them up and running very quickly. “The installation team were lovely, friendly guys and they did a wonderful job getting us up and running,” Brent Wilcox said. The staff in California including, Mark Stratford (USA QC Manager), Maria Mendoza (Warehouse Staff) and Shawn Anderson (USA Purchasing) have worked on getting the machine programed and loaded.

California added a workstation and an arm to make it easy and convenient to use. They have also put a table and banding machine close to the shuttles to streamline pulling and packing. The California depot is excited to play with their new toys and hopes to get more in the future to modernize the warehouse and increase output.

As Penn Elcom continue to grow, we see this as the next step to help facilitate our evolution and allow us to manage and ship orders even more efficiently.