This is the first machine Roger Willems ever bought and it ran millions and millions of Penn Elcom parts. It still works and could keep on producing parts but it is kept in our manufacturing facilities in Washington as memorabilia to remind us that this whole adventure began with this tiny metal bundle.

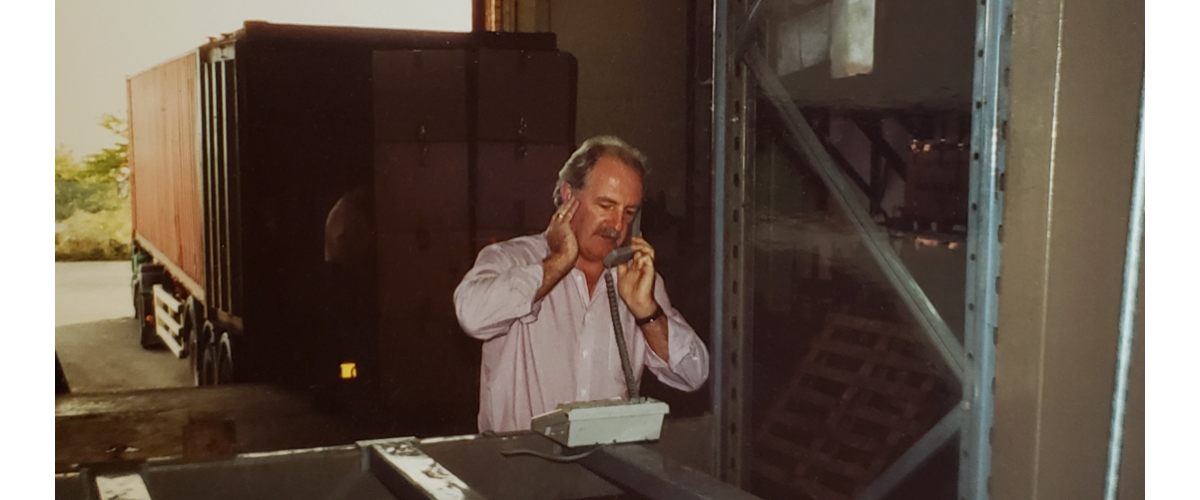

Chairman of Penn Elcom, Roger Willems told us more about this Vickers-Armstrongs Ltd. machine that started it all…

“I paid £150 for it from a company called ‘DEL Machines’ who were a second-hand machine dealer back in 1974. We had just received a job which involved punching a slot into aluminium extrusion for a company called ‘Concord Lighting`. We had great affection for her – the machine did about a million operations… it just never let us down!”

Although the machine is no longer being used for production in our factory, it had a long life of service and really sparked Roger’s desire to grow Penn Fabrications and was the first step in a long line of technological investments…

“We ran the machine in Penn Fabrications’ first factory for 15 years. Then in Washington, UK for a further 12 years. During these later years, we would use it for short runs of general small parts. She really was a foundation machine and the start of Penn Elcom as it is today. We were just learning back then, and she was incredibly reliable and fit for purpose. With the money we made from the parts she produced, we were able to evolve by adding bigger and more technical machines to our inventory over time."

From the purchase of the Penn Elcom Mascot (named so by Penn Elcom staff after its ‘retirement’) in the '70s until now in 2022, we have acquired over 165 machines in the UK alone. Other than the Mascot, there is one machine in particular that Roger has a soft spot for…

“I looked 35 years ago at a similar machine and thought it was so complex and clever, but far too expensive for us at the time. One night I was looking online at a similar machine but the company were super slow in getting back to me with any accurate costs or information. I then typed in “Salvagnini” and up came the company we still use today – I sent a message asking if I could get an estimate on costs and about 5 minutes later my mobile rang. The voice said: “Hello Roger, it’s George here. I know you as I used to work for one of your other vendors”. George gave me the price pretty much instantly and answered all of my questions so we were able to make an informed decision. It was a substantial purchase for us at that time, around £50,000 some 35 years ago (however nowadays a new Salvagnini will cost around £700,000)! But in the end, we decided to go for it and what a great decision that was. We now have 3 Salvagnini machines, with another to come shortly. They are a love affair for me…

They are so incredibly clever – they just amaze me. They do things that are impossible and I swear my Salvagnini winks at me sometimes and just says “don’t worry, I know what to do”. My workforce loves them. I was excited to show my wife the first Salvagnini machine. I opened the introduction with “this is my other girlfriend” and my lovely wife allowed me to keep her. Everyone who sees these machines is interested in them, seeing them working and how they bend the metal… `Salvi’s` is my love."

There is no question that the machines purchased by Roger all those years ago formed the roots of Penn Elcom. But it is more than just metal, parts and technology that have propelled us to where we are today…

“I am truly in awe of the people who continue this `old-fashioned` trade/way of manufacturing. They have wonderful skills, and their commitment to work and producing high-quality results is fantastic. I am proud to say we have many of these such individuals at Penn Elcom. In the UK alone, we process 3,000 tonnes of metal each year and send it all over the world - there is not a stage that does not have our parts. And all of this is down to our people. Our staff. We have so many fantastic employees, many of them with over 20 years at Penn Elcom, and 7 who have been with us for over 40 years. All of them, both old and new, are the reason we are where we are today, and I thank each and every one of them for their hard work, discipline and determination to continue to make Penn Elcom a global success and leading brand."